FPD Inspection

Array

-

AOI

This equipment is developed to examine defects caused by particles, pin holes, chips, etc. during the panel manufacturing process using Vision.

-

BP Macro AOI

This equipment is an equipment that inspects stain defects in various processes such as photo, cleaning, and P.I. printing during the OLED manufacturing process, and can detect and classify weak stains using unique optical systems.

-

ELA Auto Macro

This equipment is located after the ELA process during the OLED manufacturing process, and the stain defect according to the crystallization condition is photographed and inspected through Vision.

-

CF Auto Macro

This equipment is located after the color Filter process during the OLED manufacturing process and is an Inline facility that detects stains and foreign substances caused by coating.

-

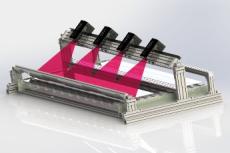

Mura inspector (In-Line)

Based on the know-how obtained from the actual production line response, this equipment detects the Mura defect of Glass after the P.I printing process is completed, and is designed with Module Type optimized for In-Line response for rapid installation and inspection considering user convenience.

-

Chip / Crack Inspector

This equipment is designed with Module Type optimized for In-Line response so that it can be installed and inspected quickly and accurately considering user convenience. Based on the know-how obtained from the actual production line response, the equipment is installed in the middle or the end of all LCD/ OLED processes to detect Crack, Chip, Broken etc. formed in the logistics glass.

-

OTFT Inspection System

Full Auto System equipment that detects defects using high resolution Line Scan Camera and Review Camera to apply the glass.