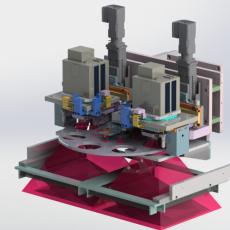

전체 제품

전체 제품

-

Cell lighting inspector_Module

This equipment uses Vision to distinguish foreign substances and defects after turning on the injected cell, and detects defects in orthogonal, staining, and viewing angle, provides customized inspection solutions to customers, and is a validated system through mass-production delivery.

-

CIS inspector

This equipment detects various stain defects (black wire, black spot, white spot, etc.) during the color filter and Micro Lens process using the optical meter, and it is a device that can detect Defocus in the Micro Lens process.

-

Wafer Ink Marking

Equipment that automatically marks the defective chip part of Wafer. Equal Ink Dot Marking, variable Ink Dot size from 125um to 700um, takes up to 2-3 minutes to improve productivity. Using vision, inspection of the location and size of the dotted ink

-

Pad inspector (Automatic probe cheker)

It is an equipment that inspects probe stain which is on Pad using optical system, automatically detects abnormality of Probe. Moreover, this equipment automatically analyzes the Probe Card Align status or the status of each probe, and simultaneously inspects the particle around the pad, analyzes the Fuse image, and detects whether it has been accurately repaired.

-

Film Inspector

This equipment which is using Vision is designed to inspect defects caused by Particle and Handling Miss during the manufacturing process of Film for Mobile.

-

Indentation impression inspector

This equipment is a Module process facility designed to inspect the condition of the ACF Film after the process of bonding the IC and FPC to the LCD panel. It can be applied to flexible because it can do auto focusing in real time.

-

压痕检查设备

本设备作为Module工程设备,是在将IC和FPC Bonding的LCD Panel的工程后,为了检查ACF Film的Bonding状态而制作的设备。可实时自动聚焦,可适用于Flexible。

-

Film检查设备

本设备是为了检查Mobile用Film 制造工艺中发生的Particle、Handling Miss所产生的不良现象而开发的通过Vision 检查的装备。

-

Pad检查设备(Automatic Probe Checker)

为了评价Electric特性,在Pad部Probing的Probe印记 通过光学系统进行 Inspection,自动检测出Probe是否异常,自动分析 Probe Card Align状态或各Probe的状态,同时检查Pad周边的 Particle,分析Fuse图像,检测出是否 正确成为Repair的装备。